Comprehensive Application Guide for SEG Lightboxes: End-to-End Solutions from Selection to Transportation

Time : 2025-12-18

Comprehensive Application Guide for SEG Lightboxes: End-to-End Solutions from Selection to Transportation

In exhibition displays, retail terminals, outdoor advertising, and other scenarios, SEG (Silicone Edge Graphics) lightboxes are gradually replacing traditional lightboxes as the preferred choice due to their ultra-thin design, energy efficiency, and easy maintenance. This article provides a one-stop application solution covering selection, installation, performance comparison, overseas transportation, and energy-saving calculations, helping to efficiently implement various display projects.

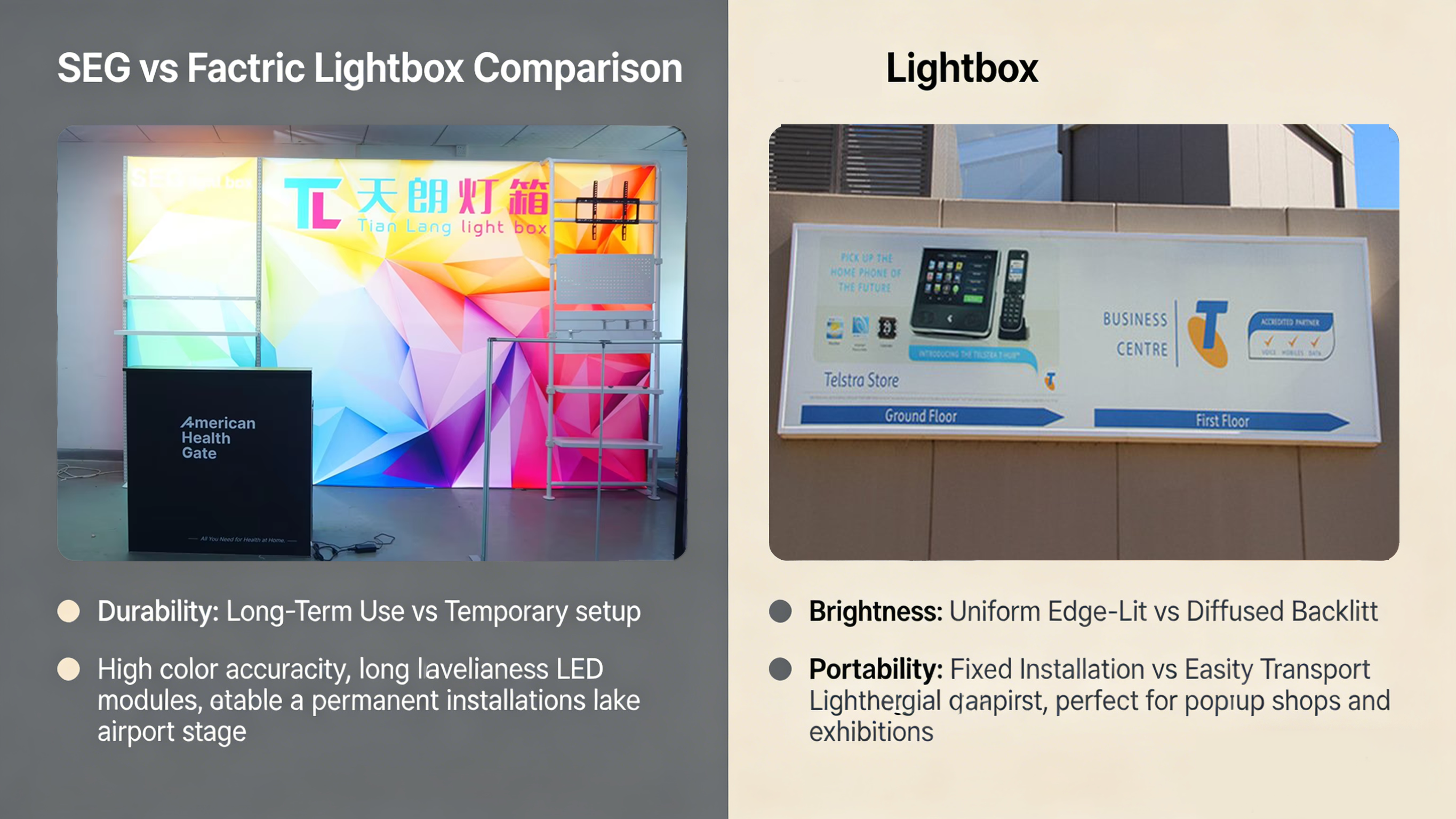

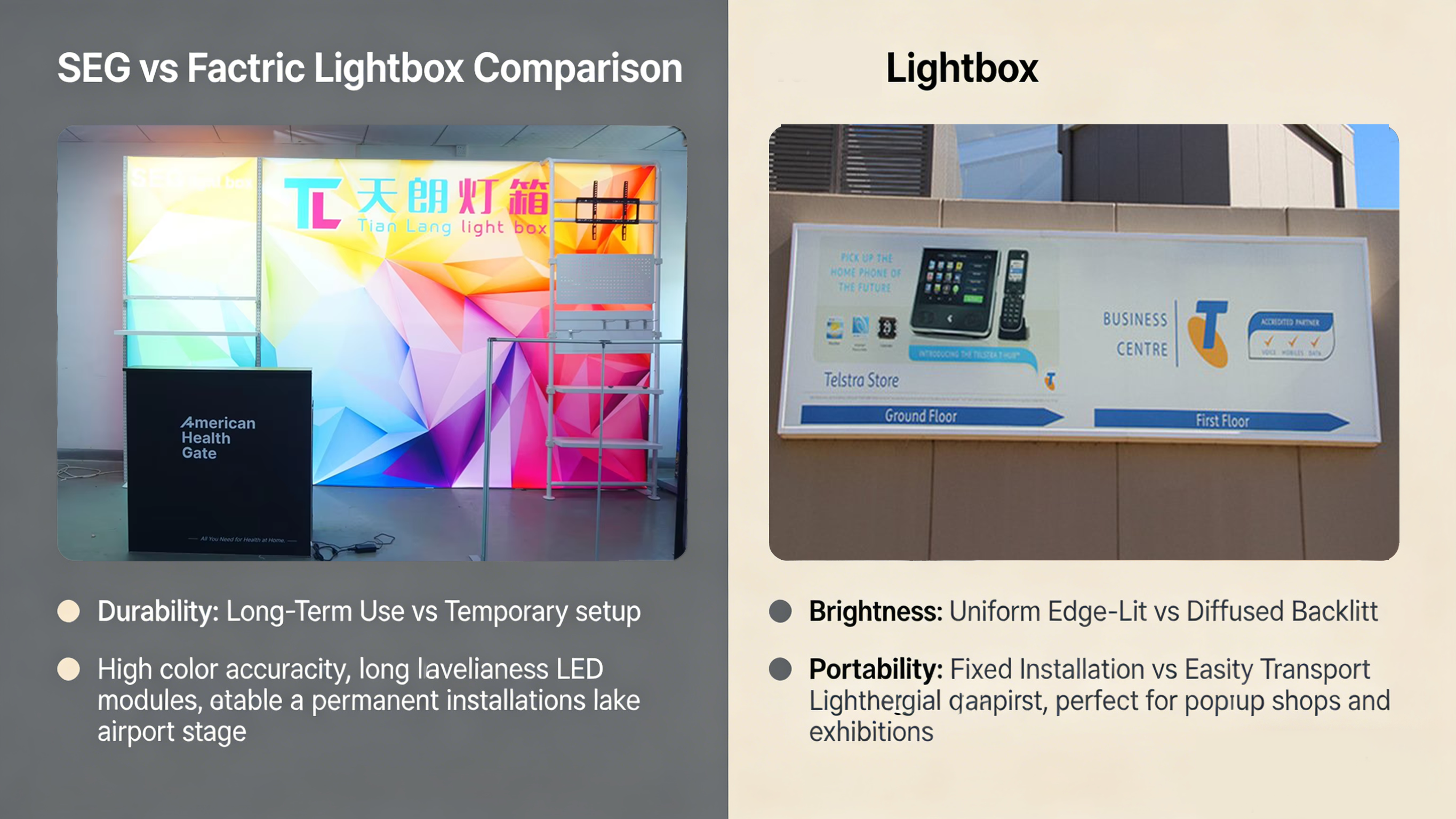

I. Core Differences Between SEG Lightboxes and Traditional Lightboxes

SEG lightboxes (also known as fabric tension lightboxes) differ essentially from traditional fluorescent lightboxes in core performance, with distinct advantages in practical applications:

In addition to parametric advantages, the "invisible frame" design of SEG lightboxes (silicone edges fully embedded in aluminum alloy frames) enables seamless splicing, delivering stronger visual impact—especially suitable for high-end exhibitions, retail stores, and similar scenarios.

II. Scientific Decision-Making for Exhibition Lightbox Selection: Thickness and Type

(1) Three Core Factors for Thickness Selection

- Scenario Adaptation: For indoor displays, prioritize ultra-thin models (3-8cm); outdoor applications require ≥8cm for enhanced wind resistance; shopping mall counters recommend 8-15cm to balance aesthetics and stability.

- Light Source Type: LED light sources enable ultra-thin designs (2.5-5cm); light guide plate technology can achieve 1-2cm thickness; fluorescent tubes require ≥15cm thickness.

- Size Matching: Small sizes ( choose 3-5cm; medium sizes (1-3m²) choose 5-8cm; large sizes (3m²) require ≥10cm with reinforced structural support.

(2) Recommended Thickness for Common Lightbox Types

Quick Selection Formula: Thickness (cm) = 0.1 × Maximum lightbox side length (cm) + 2-5cm safety margin

(3) Key Points to Avoid Mistakes in Selection

- Prioritize 6063-T5 aluminum alloy for frames with wall thickness ≥1.5mm; avoid low-cost thin-walled profiles (mm).

- Light sources should meet 5000-6500K color temperature and ≥90 CRI; outdoor scenarios require IP65 protection rating.

- Choose polyester fiber materials (180-220g/m²); outdoor use requires UV-resistant coating, and mold-proof fabrics for high-humidity areas.

- Prefer suppliers offering integrated "design-production-installation-maintenance" services to reduce communication costs.

III. Practical Installation Guide for SEG Lightboxes

(1) Core Installation Steps

- Frame Assembly: Insert corner connectors into the ends of aluminum alloy profiles, splice the four corners and tighten screws, ensuring flatness deviation ≤2mm/m.

- Light Source Installation: Fix LED strips inside the frame, connect a power adapter with matching voltage, and test light uniformity.

- Fabric Installation (Critical Step): Start from one corner and embed the silicone edge into the frame groove; fix the four corners first, then work toward the center. Two people are required to avoid uneven force, ensuring the fabric is taut and wrinkle-free.

(2) Operation Points for Different Installation Types

(3) Practical Tips

- Clean the frame groove before installation to avoid dust affecting silicone adhesion.

- Two people are required for large lightboxes (2m) to prevent fabric deformation.

- After installation, gently pull the fabric to check firmness and ensure no light leakage gaps.

IV. Comprehensive Transportation Plan for Overseas Exhibition Materials

The core of overseas exhibition lightbox transportation lies in "disassembled packaging + rational transportation method selection," balancing cost and safety:

(1) Scientific Packaging Plan

- Classified Packaging: Disassemble frames and wrap edges with bubble wrap; fold/roll fabrics and place in waterproof bags; electronic components (power supplies, controllers) require anti-static packaging and separate cartons.

- Reinforcement Treatment: Fill cartons with foam particles; seal seams with ≥5cm wide tape in an "I" shape.

- Clear Labeling: Mark "Fragile," "This Side Up," exhibition name, booth number, and carton number/total quantity on outer cartons.

(2) Transportation Method Selection Guide

Recommended Combined Plan: Sea freight for heavy items (e.g., frames) and air freight/express for fragile items (e.g., fabrics, electronic components) to balance cost and timeliness.

(3) Customs Clearance and Emergency Preparation

- Required Documents: Stamped commercial invoice, Chinese-English packing list, copy of exhibition invitation, certificate of origin (for some countries).

- Insurance Strategy: Independently insure high-value items (5000 RMB) with insured value 110% of declared value; batch insurance for general materials (rate 0.3-0.5%).

- Emergency Plan: Prepare electronic backups of key materials and 1-2 spare parts for critical components to be shipped with the goods.

EN

EN

FR

FR DE

DE PT

PT ES

ES AR

AR BG

BG HR

HR CS

CS DA

DA FI

FI NL

NL EL

EL IT

IT JA

JA KO

KO NO

NO PL

PL RO

RO RU

RU SV

SV CA

CA TL

TL IW

IW LV

LV LT

LT SR

SR SK

SK SL

SL ET

ET MT

MT TH

TH FA

FA AF

AF MS

MS SW

SW GA

GA KA

KA