ผู้จัดแสดงสามารถดูแลบูธแสดงสินค้าเพื่อการใช้งานระยะยาวได้อย่างไร

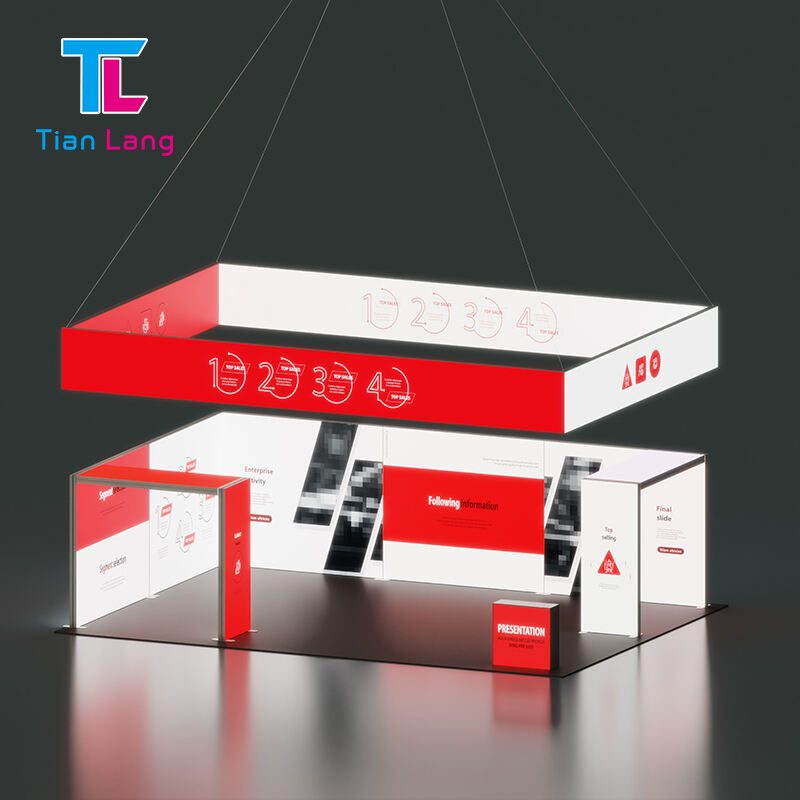

งานแสดงสินค้า การเข้าร่วมแสดงสินค้าถือเป็นการลงทุนที่สำคัญสำหรับธุรกิจที่ต้องการขยายการมีอยู่ในตลาดและสร้างโอกาสในการขาย ส่วนความสำเร็จของงานแสดงเหล่านี้ขึ้นอยู่กับคุณภาพและความทนทานของ งานแสดงสินค้า บูธแสดงสินค้า ซึ่งทำหน้าที่เป็นช่องทางหลักในการนำเสนอแบรนด์และการมีปฏิสัมพันธ์กับลูกค้า ผู้แสดงสินค้ามืออาชีพเข้าใจดีว่า การดูแลรักษาระบบแสดงสินค้านี้จำเป็นต้องมีการดูแลอย่างเป็นระบบ การวางแผนเชิงกลยุทธ์ และความใส่ใจในรายละเอียดอย่างต่อเนื่อง เพื่อให้มั่นใจได้ว่าจะได้รับผลตอบแทนจากการลงทุนสูงสุดตลอดหลาย ๆ เหตุการณ์

กลยุทธ์การบำรุงรักษาที่มีประสิทธิภาพนั้นครอบคลุมมากกว่าเพียงแค่การทำความสะอาด โดยรวมถึงเทคนิคการจัดเก็บอย่างเหมาะสม ขั้นตอนการตรวจสอบชิ้นส่วน และตารางการเปลี่ยนอะไหล่ล่วงหน้า บริษัทที่นำโปรแกรมการบำรุงรักษาอย่างครอบคลุมไปใช้มักพบว่า นิทรรศการ การลงทุนช่วยสร้างผลลัพธ์ที่เหนือกว่าในด้านตัวชี้วัดประสิทธิภาพ ขณะเดียวกันก็ลดต้นทุนการดำเนินงานในระยะยาว ภูมิทัศน์การแข่งขันของงานแสดงสินค้ายุคใหม่ต้องการให้ผู้แสดงสินค้านำเสนอภาพลักษณ์ที่ประณีตและเป็นมืออาชีพ ซึ่งสะท้อนคุณค่าของแบรนด์และการวางตำแหน่งทางการตลาดอย่างสอดคล้องกันในสถานที่ต่างๆ และช่วงเวลาต่างๆ

องค์ประกอบสำคัญของการบำรุงรักษาบูธแสดงสินค้า

โครงสร้างและส่วนประกอบโครง

รากฐานของงานแสดงสินค้าที่ทนทานอยู่ที่ชิ้นส่วนโครงสร้าง ซึ่งต้องได้รับการตรวจสอบและดูแลเป็นประจำเพื่อให้มั่นใจในความปลอดภัยและรูปลักษณ์ที่น่าดึงดูด โครงอลูมิเนียม ข้อต่อ และกลไกยึดรองรับ ควรได้รับการตรวจสอบเพื่อหาสัญญาณของความสึกหรอ ความกัดกร่อน หรือความเสียหายที่อาจทำให้ความมั่นคงของบูธลดลงในระหว่างการติดตั้งหรือตลอดช่วงระยะเวลาของการจัดแสดง ผู้แสดงสินค้ามืออาชีพมักจะจัดทำรายการตรวจสอบอย่างละเอียดเพื่อบันทึกสภาพของแต่ละองค์ประกอบโครงสร้าง โดยระบุปัญหาที่ต้องได้รับการแก้ไขทันที หรือต้องติดตามในอนาคต

การหล่อลื่นส่วนที่เคลื่อนไหวเป็นประจำ เช่น ขาแขนแบบเลื่อนและข้อต่อแบบปรับระดับได้ จะช่วยป้องกันชิ้นส่วนติดขัด และทำให้กระบวนการประกอบดำเนินไปอย่างราบรื่น โปรแกรมการบำรุงรักษาคุณภาพสูงยังรวมถึงการทดสอบความแข็งแรงของชิ้นส่วนรับน้ำหนักเป็นระยะ เพื่อตรวจสอบว่าโครงแสดงสามารถรองรับกราฟิก อุปกรณ์ไฟส่องสว่าง และชิ้นส่วนเชิงโต้ตอบได้อย่างปลอดภัย การดำเนินการอย่างเป็นระบบเช่นนี้ช่วยป้องกันความล้มเหลวที่อาจเกิดค่าใช้จ่ายสูงในช่วงเวลาสำคัญของการจัดนิทรรศการ พร้อมทั้งรักษารูปลักษณ์มืออาชีพที่ผู้เข้าชมคาดหวังจากแบรนด์ชั้นนำ

กราฟิกและองค์ประกอบภาพ

กราฟิกภาพเป็นองค์ประกอบที่มองเห็นได้ชัดเจนที่สุดของระบบบูธแสดงสินค้าในงานแสดงสินค้า และต้องได้รับการดูแลเป็นพิเศษเพื่อรักษาระดับความประทับใจและความเรียบร้อยในเชิงมืออาชีพ ผ้ากราฟิกคุณภาพสูง ป้ายไวนิล และแผ่นพิมพ์ต่างๆ สามารถใช้งานได้หลายครั้งหากดูแลอย่างเหมาะสม แต่ต้องอาศัยขั้นตอนการจัดการและการจัดเก็บที่เฉพาะเจาะจง เพื่อป้องกันไม่ให้เกิดรอยพับ จางสี หรือความเสียหายถาวร ผู้แสดงสินค้าระดับมืออาชีพจะลงทุนกับโซลูชันการจัดเก็บที่ช่วยรักษาคุณภาพของกราฟิกไว้ระหว่างการจัดงาน พร้อมทั้งอำนวยความสะดวกต่อการขนส่งและการติดตั้งอย่างง่ายดาย

ควรมีการดำเนินการตามมาตรการทำความสะอาดเป็นประจำ โดยคำนึงถึงวัสดุกราฟิกที่แตกต่างกันอย่างเหมาะสม ใช้สารทำความสะอาดและเทคนิคที่ผู้ผลิตแนะนำ เพื่อรักษาความสดใสของสีและความทนทานของวัสดุ ปัจจัยด้านสิ่งแวดล้อม เช่น ความเข้มของแสง ระดับความชื้น และความถี่ในการสัมผัส ล้วนมีผลต่ออายุการใช้งานของกราฟิก ทำให้ itจำเป็นต้องติดตามตรวจสอบปัจจัยเหล่านี้และปรับตารางการบำรุงรักษาให้เหมาะสม การวางแผนการเปลี่ยนอุปกรณ์อย่างเป็นยุทธศาสตร์ ช่วยให้ผู้แสดงสินค้าสามารถปรับปรุงองค์ประกอบภาพลักษณ์หลักก่อนที่จะเริ่มมีการสึกหรอมากเกินไป ซึ่งช่วยรักษาภาพลักษณ์ของแบรนด์ระดับพรีเมียมที่จำเป็นต่อความสำเร็จในการเข้าร่วมงานแสดงสินค้า

โซลูชันการจัดเก็บและการควบคุมสภาพแวดล้อม

ข้อกำหนดการจัดเก็บในสภาพแวดล้อมที่ควบคุมอุณหภูมิ

สภาพแวดล้อมในการจัดเก็บที่เหมาะสมมีบทบาทสำคัญในการยืดอายุการใช้งานของชิ้นส่วนแสดงนิทรรศการ โดยเฉพาะวัสดุที่ไวต่อสภาวะแวดล้อม เช่น อุปกรณ์อิเล็กทรอนิกส์ ผ้าพิมพ์ภาพกราฟิก และฮาร์ดแวร์ที่ผลิตด้วยความแม่นยำ อุณหภูมิที่เปลี่ยนแปลงและระดับความชื้นที่สูงเกินไป อาจทำให้วัสดุบิดงอเป็นรอย พังจากการกัดกร่อน หรือเสื่อมสภาพจนไม่สามารถนำกลับมาใช้ในนิทรรศการครั้งต่อไปได้ สถานที่จัดเก็บมืออาชีพควรรักษาระดับอุณหภูมิให้อยู่ในช่วง 60-75 องศาฟาเรนไฮต์อย่างสม่ำเสมอ และควบคุมระดับความชื้นสัมพัทธ์ไม่ให้เกิน 50 เปอร์เซ็นต์ เพื่อให้การรักษาชิ้นส่วนมีประสิทธิภาพสูงสุด

พื้นที่จัดเก็บเฉพาะควรป้องกันสินค้าจากแสงแดดโดยตรง ฝุ่นที่อาจสะสม และความเสียหายจากน้ำที่อาจเกิดขึ้นในสภาพแวดล้อมของคลังสินค้าทั่วไป ผู้แสดงสินค้าจำนวนมากที่ประสบความสำเร็จจะลงทุนในตู้จัดเก็บพิเศษหรือพื้นที่ในสถานที่เฉพาะที่ช่วยให้สามารถจัดเรียงชิ้นส่วนได้อย่างเป็นระบบและจัดการสินค้าคงคลังได้อย่างง่ายดาย วิธีการแบบเป็นระบบเช่นนี้ช่วยลดเวลาในการติดตั้งที่สถานที่จัดแสดงสินค้า ขณะเดียวกันก็รับประกันว่าองค์ประกอบทั้งหมดของการแสดงสินค้ายังคงอยู่ในสภาพที่เหมาะสมระหว่างงานต่างๆ

การจัดการสินค้าคงคลังและการติดตามชิ้นส่วน

ระบบบริหารสินค้าคงคลังอย่างครบวงจรช่วยให้ผู้จัดแสดงสามารถติดตามสภาพของชิ้นส่วน ประวัติการใช้งาน และกำหนดการบำรุงรักษาตลอดหลายรอบการจัดแสดงนิทรรศการ แพลตฟอร์มติดตามแบบดิจิทัลสามารถบันทึกข้อมูลจำเพาะของชิ้นส่วน กิจกรรมการบำรุงรักษา และกำหนดการเปลี่ยนชิ้นส่วน เพื่อเพิ่มประสิทธิภาพในการดำเนินงานของบูธและการวางแผนงบประมาณ แนวทางการจัดการอย่างเป็นระบบเช่นนี้ช่วยระบุรูปแบบของการสึกหรอและอัตราการชำรุดของชิ้นส่วน ทำให้สามารถดำเนินกลยุทธ์การบำรุงรักษาเชิงรุกได้ เพื่อป้องกันปัญหาในช่วงเวลาที่สำคัญของการจัดแสดงนิทรรศการ

การจัดการสินค้าคงคลังอย่างมีประสิทธิภาพยังรวมถึงการมีชิ้นส่วนอะไหล่พร้อมใช้งาน เพื่อให้มั่นใจว่าการซ่อมแซมหรือเปลี่ยนชิ้นส่วนเล็กๆ สามารถดำเนินการได้โดยไม่รบกวนกำหนดการจัดแสดง ผู้จัดแสดงมืออาชีพมักจะเก็บกราฟิกสำรอง ชิ้นส่วนฮาร์ดแวร์ และเครื่องมือที่จำเป็นไว้ เพื่อให้สามารถแก้ปัญหาได้อย่างรวดเร็วในระหว่างการติดตั้งหรือตลอดช่วงระยะเวลาการจัดแสดง การวางแผนสำรองเหล่านี้ถือเป็นการลงทุนเพิ่มเติมเล็กน้อย แต่สามารถป้องกันความสูญเสียทางการเงินและผลกระทบต่อชื่อเสียงของแบรนด์ได้เมื่อเกิดปัญหาที่ไม่คาดคิด

มาตรการการขนส่งและการจัดการ

ระบบบรรจุภัณฑ์ป้องกัน

ขั้นตอนการขนส่งถือเป็นช่วงเวลาที่มีความเสี่ยงสูงที่สุดต่อความเสียหายของบูธแสดงสินค้า การใช้บรรจุภัณฑ์ป้องกันจึงเป็นสิ่งจำเป็นเพื่อรักษาองค์ประกอบต่างๆ ให้อยู่ในสภาพดีระยะยาว กล่องจัดส่งมืออาชีพควรให้การรองรับและซับแรงกระแทกที่เพียงพอ เพื่อป้องกันความเสียหายจากแรงปะทะ และสามารถรองรับขนาดและน้ำหนักเฉพาะของแต่ละชิ้นส่วนของบูธแสดงสินค้าได้ แผ่นโฟมสำหรับใส่ตามแบบเฉพาะ ตัวคั่นที่มีการบุนวม และวัสดุที่ช่วยดูดซับแรงสะเทือน ล้วนช่วยรักษาความสมบูรณ์ของชิ้นส่วนระหว่างการขนส่งผ่านรูปแบบการขนส่งต่างๆ

ขั้นตอนการบรรจุหีบห่อเชิงกลยุทธ์ควรจัดเรียงส่วนประกอบอย่างเป็นระบบเพื่ออำนวยความสะดวกในการติดตั้งอย่างมีประสิทธิภาพ พร้อมทั้งลดความจำเป็นในการเคลื่อนย้ายที่สถานที่จัดแสดงนิทรรศการ การกระจายของน้ำหนักภายในตู้ขนส่งมีผลต่อต้นทุนการขนส่งและความปลอดภัยในการจัดการ ทำให้การสมดุลระหว่างความต้องการป้องกันและข้อพิจารณาด้านโลจิสติกส์ที่ปฏิบัติได้จริงมีความสำคัญ ผู้จัดแสดงมืออาชีพมักพัฒนาขั้นตอนการบรรจุหีบห่อมาตรฐานที่รับประกันระดับการป้องกันอย่างต่อเนื่อง และช่วยปรับกระบวนการเตรียมงานให้มีความคล่องตัวสำหรับการจัดแสดงหลายครั้ง

แนวทางปฏิบัติที่ดีที่สุดสำหรับการติดตั้งและการถอดถอน

การจัดการอย่างระมัดระวังในขั้นตอนการติดตั้งและถอดประกอบมีผลอย่างมากต่ออายุการใช้งานของบูธแสดงสินค้าในงานแสดงสินค้าและชิ้นส่วนต่างๆ ทีมติดตั้งมืออาชีพควรได้รับการฝึกอบรมเกี่ยวกับเทคนิคการจัดการที่ถูกต้อง ลำดับการประกอบชิ้นส่วน และมาตรการด้านความปลอดภัยที่ป้องกันความเสียหายในช่วงเวลาสำคัญเหล่านี้ ขั้นตอนการติดตั้งอย่างเป็นระบบจะช่วยลดแรงกระทำต่อจุดเชื่อมต่อและองค์ประกอบโครงสร้าง พร้อมทั้งรับประกันว่าชิ้นส่วนทั้งหมดได้รับการยึดและจัดเรียงอย่างถูกต้องเพื่อประสิทธิภาพสูงสุด

การจัดทำเอกสารบันทึกขั้นตอนการติดตั้งและถอดถอนช่วยให้สามารถระบุโอกาสในการปรับปรุงที่อาจเกิดขึ้นได้ ขณะเดียวกันก็รับประกันความสอดคล้องกันในสถานที่จัดแสดงสินค้าที่แตกต่างกันและทีมติดตั้งที่หลากหลาย การจัดสรรเวลาให้เพียงพอสำหรับการถอดประกอบอย่างระมัดระวังจะช่วยป้องกันการเร่งรีบ ซึ่งมักนำไปสู่ความเสียหายหรือสูญหายของชิ้นส่วน ขณะที่ขั้นตอนการบรรจุหีบห่ออย่างเป็นระบบจะรับประกันว่าทุกองค์ประกอบได้รับการป้องกันอย่างเหมาะสมระหว่างการขนส่งไปยังสถานที่จัดเก็บหรือสถานที่จัดแสดงงานต่อไป

การผสานเทคโนโลยีและการดูแลชิ้นส่วนดิจิทัล

การจัดการหน้าจออิเล็กทรอนิกส์

การแสดงนิทรรศการแบบทันสมัยมีการใช้หน้าจอดิจิทัล ระบบไฟ LED และองค์ประกอบเทคโนโลยีเชิงโต้ตอบที่ต้องอาศัยขั้นตอนการบำรุงรักษาพิเศษ เพื่อให้มั่นใจว่าจะทำงานได้อย่างเสถียรตลอดหลาย ๆ กิจกรรม การทำงานของชิ้นส่วนอิเล็กทรอนิกส์มีความไวต่อสภาพแวดล้อม แรงกระแทกทางกายภาพ และการเปลี่ยนแปลงของกระแสไฟฟ้า ซึ่งอาจเกิดขึ้นได้ในการจัดแสดงทั่วไป การทดสอบองค์ประกอบอิเล็กทรอนิกส์ทั้งหมดอย่างสม่ำเสมอ ก่อนแต่ละงานนิทรรศการ จะช่วยระบุปัญหาที่อาจเกิดขึ้นได้ตั้งแต่เนิ่น ๆ ในขณะที่ชิ้นส่วนสำรองยังคงมีพร้อม และยังมีเวลาเพียงพอสำหรับการติดตั้ง

ระบบจัดการพลังงานควรรวมถึงการป้องกันไฟกระชาก การจัดการสายเคเบิลอย่างเหมาะสม และโซลูชันสำหรับแหล่งจ่ายไฟสำรอง เพื่อป้องกันความเสียหายจากปัญหาด้านไฟฟ้าที่มักเกิดขึ้นในสภาพแวดล้อมของการจัดแสดงนิทรรศการ ผู้จัดแสดงระดับมืออาชีพมักจัดทำเอกสารอย่างละเอียดเกี่ยวกับข้อมูลจำเพาะของชิ้นส่วนอิเล็กทรอนิกส์ ข้อมูลการรับประกัน และรายชื่อผู้ติดต่อฝ่ายสนับสนุนทางเทคนิค เพื่อให้สามารถแก้ไขปัญหาได้อย่างรวดเร็วเมื่อเกิดปัญหาขึ้นในช่วงเวลาสำคัญของการจัดแสดง

ซอฟต์แวร์และการจัดการเนื้อหา

การจัดการเนื้อหาดิจิทัลต้องอาศัยขั้นตอนการสำรองข้อมูลอย่างเป็นระบบ โปรโตคอลควบคุมเวอร์ชัน และการทดสอบความเข้ากันได้ เพื่อให้มั่นใจในการทำงานอย่างราบรื่นในสถานที่จัดแสดงและสภาพแวดล้อมทางเทคนิคที่แตกต่างกัน การอัปเดตซอฟต์แวร์และการติดตั้งแพตช์ด้านความปลอดภัยอย่างสม่ำเสมอยังช่วยรักษาเสถียรภาพของระบบ และป้องกันภัยคุกคามด้านไซเบอร์ที่อาจทำให้ข้อมูลธุรกิจที่สำคัญหรือการทำงานของการแสดงผลเสียหายระหว่างการจัดแสดงนิทรรศการ

กำหนดการอัปเดตเนื้อหาควรสอดคล้องกับวัตถุประสงค์ทางการตลาดและการพัฒนาข้อความของแบรนด์ พร้อมทั้งรักษาระบบความเข้ากันได้ทางเทคนิคกับฮาร์ดแวร์จอแสดงผลที่มีอยู่ การจัดแสดงระดับมืออาชีพมักพัฒนารูปแบบเนื้อหาและข้อกำหนดทางเทคนิคที่เป็นมาตรฐาน เพื่อให้มั่นใจในประสิทธิภาพที่สม่ำเสมอในสถานที่จัดแสดงต่างๆ และเพื่ออำนวยความสะดวกในการอัปเดตและปรับเปลี่ยนอย่างมีประสิทธิภาพเมื่อความต้องการทางธุรกิจมีการเปลี่ยนแปลง

การบริหารต้นทุนและการวางแผนงบประมาณ

การวิเคราะห์ต้นทุนการบำรุงรักษา

การติดตามต้นทุนอย่างครอบคลุมช่วยให้ผู้จัดแสดงสามารถเข้าใจผลกระทบทางการเงินที่แท้จริงจากการเป็นเจ้าของบูธแสดงสินค้า ขณะเดียวกันก็ช่วยระบุโอกาสในการปรับปรุงและเพิ่มประสิทธิภาพ ค่าใช้จ่ายในการบำรุงรักษาตามปกติควรเปรียบเทียบกับต้นทุนการเปลี่ยนใหม่ เพื่อกำหนดกลยุทธ์การจัดการวงจรชีวิตของชิ้นส่วนอย่างเหมาะสม โดยคำนึงถึงสมดุลระหว่างความต้องการด้านประสิทธิภาพและการจำกัดงบประมาณ แนวทางเชิงวิเคราะห์นี้ช่วยให้สามารถตัดสินใจอย่างมีข้อมูลเกี่ยวกับการอัปเกรดชิ้นส่วน ตารางการเปลี่ยนชิ้นส่วน และลำดับความสำคัญของการลงทุนด้านการบำรุงรักษา

ผู้แสดงสินค้ามืออาชีพมักพบว่าการลงทุนในการบำรุงรักษาเชิงรุกจะให้ผลประหยัดในระยะยาวอย่างมาก เมื่อเทียบกับกลยุทธ์การเปลี่ยนชิ้นส่วนแบบเร่งด่วนที่ต้องจัดซื้อในราคาสูง การวิเคราะห์ต้นทุนอย่างละเอียดยังเปิดเผยรูปแบบของประสิทธิภาพและอัตราการเสียหายของชิ้นส่วน ซึ่งช่วยสนับสนุนการตัดสินใจในการซื้อในอนาคตและการพัฒนาแนวทางปฏิบัติด้านการบำรุงรักษา

การเพิ่มประสิทธิภาพผลตอบแทนจากการลงทุน

การวางแผนการบำรุงรักษาอย่างเป็นกลยุทธ์จะช่วยยืดอายุการใช้งานของการลงทุนด้านการจัดแสดง ขณะเดียวกันก็เพิ่มประสิทธิภาพสูงสุดในการสนับสนุนเป้าหมายการพัฒนาธุรกิจตลอดหลายงานแสดงสินค้าและกิจกรรมทางการตลาด ตัวชี้วัดประสิทธิภาพควรรวมถึงความมีประสิทธิภาพในการติดตั้ง ความสม่ำเสมอของผลกระทบด้านภาพลักษณ์ และปัจจัยด้านความน่าเชื่อถือในการดำเนินงาน ซึ่งส่งผลโดยตรงต่อความสำเร็จของการจัดแสดงและการสร้างโอกาสทางการขาย

ปัจจัยพิจารณาสำหรับการวางแผนระยะยาวควรครอบคลุมโอกาสในการอัปเกรดชิ้นส่วน แนวโน้มการพัฒนาของเทคโนโลยี และข้อกำหนดของการจัดแสดงที่อาจเปลี่ยนแปลงไป ซึ่งอาจมีผลต่อกลยุทธ์การบำรุงรักษาและการตัดสินใจลงทุน ผู้จัดแสดงมืออาชีพมักจัดทำแผนการบำรุงรักษาและการเปลี่ยนชิ้นส่วนในหลายปี โดยให้สอดคล้องกับรอบการจัดสรรงบประมาณ พร้อมทั้งรักษามาตรฐานการนำเสนอแบรนด์อย่างต่อเนื่องในกิจกรรมการจัดแสดงทุกครั้ง

คำถามที่พบบ่อย

ควรตรวจเช็คชิ้นส่วนของแผงแสดงสินค้าในการเจรจาการค้าอย่างมืออาชีพบ่อยเพียงใด

ตารางการตรวจสอบโดยผู้เชี่ยวชาญขึ้นอยู่กับความถี่ในการใช้งานและประเภทของชิ้นส่วน แต่ผู้เชี่ยวชาญส่วนใหญ่แนะนำให้ประเมินอย่างละเอียดหลังจากจัดแสดงครบ 3 ถึง 5 ครั้ง หรือทุกปีสำหรับชุดแสดงที่ใช้น้อยกว่า ชิ้นส่วนโครงสร้างต้องได้รับการตรวจสอบบ่อยครั้งมากกว่ากราฟิก ส่วนชิ้นส่วนอิเล็กทรอนิกส์ควรได้รับการทดสอบก่อนการจัดแสดงเสมอ ไม่ว่าจะเก็บไว้นานเท่าใด การตรวจสอบเป็นประจำช่วยระบุรูปแบบการสึกหรอและปัญหาที่อาจเกิดขึ้นก่อนที่จะส่งผลกระทบต่อประสิทธิภาพในการจัดแสดง

สาเหตุที่พบบ่อยที่สุดของความเสียหายต่อแผงแสดงสินค้าระหว่างการขนส่งคืออะไร

ความเสียหายจากการขนส่งมักเกิดจากบรรจุภัณฑ์ป้องกันไม่เพียงพอ การกระจายน้ำหนักไม่เหมาะสม และการจัดการอย่างหยาบคายในขั้นตอนการโหลดหรือถอดสินค้า คุณภาพของตู้ขนส่ง วัสดุกันกระแทก และการจัดเรียงชิ้นส่วนมีผลสำคัญต่อความเสี่ยงในการเกิดความเสียหาย ในขณะที่ปัจจัยด้านสิ่งแวดล้อม เช่น อุณหภูมิที่สูงหรือต่ำเกินไป และการสัมผัสกับความชื้น อาจส่งผลกระทบต่อวัสดุที่มีความอ่อนไหวในช่วงเวลาการขนส่งที่ยาวนาน ระบบการบรรจุภัณฑ์ระดับมืออาชีพจะช่วยลดปัจจัยเสี่ยงเหล่านี้ได้อย่างเป็นระบบ

ผู้จัดแสดงสามารถพิจารณาอย่างไรว่าชิ้นส่วนของแผงแสดงสินค้าควรเปลี่ยนใหม่หรือซ่อมแซม

การตัดสินใจเปลี่ยนชิ้นส่วนควรพิจารณาค่าใช้จ่ายในการซ่อมแซม ความพร้อมของชิ้นส่วน ผลกระทบต่อประสิทธิภาพ และผลที่มีต่อภาพลักษณ์ของแบรนด์ เมื่อเทียบกับการลงทุนในชิ้นส่วนใหม่ ชิ้นส่วนที่แสดงอาการเหนื่อยล้าทางโครงสร้าง สึกหรอมาก หรือมีรูปแบบการเสียหายซ้ำๆ มักจำเป็นต้องได้รับการเปลี่ยน ขณะที่ปัญหาด้านรูปลักษณ์อาจแก้ไขได้ด้วยการซ่อมแซมเฉพาะจุดหรือการปรับปรุงสภาพ ผู้จัดแสดงมืออาชีพมักกำหนดเกณฑ์การเปลี่ยนชิ้นส่วนโดยอิงจากการวิเคราะห์ต้นทุนและผลประโยชน์ รวมถึงมาตรฐานด้านประสิทธิภาพ

สภาพการจัดเก็บแบบใดให้การป้องกันที่เหมาะสมที่สุดสำหรับวัสดุแสดงผลต่างๆ

การจัดเก็บอย่างเหมาะสมต้องอาศัยสภาพแวดล้อมที่ควบคุมอุณหภูมิและความชื้น โดยรักษาระดับอุณหภูมิให้อยู่ระหว่าง 60-75 องศาฟาเรนไฮต์ และความชื้นต่ำกว่า 50 เปอร์เซ็นต์ เพื่อป้องกันการเสื่อมสภาพของวัสดุ วัสดุแต่ละประเภทมีข้อกำหนดเฉพาะเจาะจง เช่น งานผ้าพิมพ์ภาพต้องได้รับการป้องกันจากการพับและรอยยับ ในขณะที่ชิ้นส่วนโลหะต้องจัดเก็บในสภาพแห้งเพื่อป้องกันการกัดกร่อน โซลูชันการจัดเก็บระดับมืออาชีพควรตอบสนองความต้องการที่แตกต่างกันเหล่านี้ พร้อมทั้งรองรับการบริหารจัดการสินค้าคงคลังอย่างเป็นระบบและการเข้าถึงที่สะดวกสำหรับการเตรียมงานนิทรรศการ

EN

EN

FR

FR DE

DE PT

PT ES

ES AR

AR BG

BG HR

HR CS

CS DA

DA FI

FI NL

NL EL

EL IT

IT JA

JA KO

KO NO

NO PL

PL RO

RO RU

RU SV

SV CA

CA TL

TL IW

IW LV

LV LT

LT SR

SR SK

SK SL

SL ET

ET MT

MT TH

TH FA

FA AF

AF MS

MS SW

SW GA

GA KA

KA