How to Use Modular Backdrops for Flexible and Reusable Displays?

Trade shows, exhibitions, and corporate events demand display solutions that combine visual impact with practical flexibility. Modular backdrops have emerged as the preferred choice for businesses seeking adaptable, cost-effective presentation systems that can be reconfigured for various venues and marketing objectives. These versatile display systems offer unprecedented customization options while maintaining professional aesthetics that capture audience attention and reinforce brand messaging.

Modern marketing environments require display solutions that adapt to changing spatial constraints, budget considerations, and branding requirements. Modular backdrops address these challenges by providing scalable systems that grow with business needs while delivering consistent visual quality across multiple applications. Understanding how to maximize the potential of these flexible display systems can significantly enhance marketing effectiveness and return on investment.

Understanding Modular Backdrop Systems

Core Components and Design Principles

Modular backdrops consist of interconnected panels, frames, and hardware elements that can be assembled in multiple configurations. The foundation typically includes lightweight aluminum frames that provide structural integrity while maintaining portability. Fabric panels or graphic inserts attach to these frames using various connection methods such as magnetic strips, Velcro systems, or tension mechanisms that ensure smooth, wrinkle-free presentation surfaces.

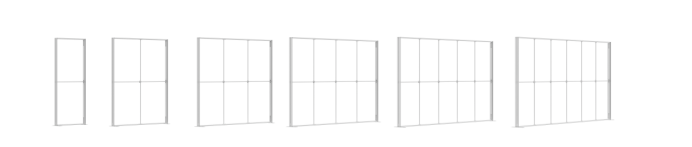

The modular design philosophy emphasizes standardized components that maintain compatibility across different sizes and layouts. This approach enables users to start with basic configurations and expand their display capabilities over time without replacing existing elements. Quality modular backdrops incorporate precision-engineered connectors that create seamless joints between panels, resulting in unified visual presentations that appear as single, continuous displays.

Material Selection and Construction Quality

Premium modular backdrops utilize high-grade aluminum alloys that provide optimal strength-to-weight ratios, ensuring durability while maintaining easy transport and setup. Frame components undergo specialized treatments to resist corrosion and maintain appearance integrity throughout extended use cycles. The engineering focuses on creating robust connection points that withstand repeated assembly and disassembly without compromising structural stability.

Fabric components represent another critical quality factor, with professional-grade materials offering superior print reproduction, color fastness, and wrinkle resistance. Advanced textile technologies enable high-resolution graphic reproduction while maintaining fabric flexibility and ease of installation. These materials must balance visual quality with practical considerations such as cleaning requirements and replacement costs for long-term value optimization.

Strategic Configuration Planning

Space Assessment and Layout Optimization

Effective utilization of modular backdrops begins with comprehensive venue analysis that considers available floor space, ceiling height restrictions, and traffic flow patterns. Successful implementations require precise measurements and understanding of any structural limitations that might affect display positioning or stability. This preliminary assessment enables optimal configuration selection that maximizes visual impact while ensuring compliance with venue regulations and safety requirements.

Layout planning should incorporate audience viewing angles, lighting conditions, and proximity to competing displays or distractions. Modular backdrops excel in environments where traditional rigid displays would create spatial conflicts or limit flexibility. Strategic positioning can create focal points that direct visitor attention while providing adequate space for meaningful interactions and product demonstrations.

Scalability and Future Expansion Considerations

Investment in modular backdrops should reflect long-term marketing strategies and anticipated growth in exhibition participation or event requirements. Initial configurations can focus on essential display needs while incorporating expansion capabilities that accommodate larger venues or enhanced presentation requirements. This forward-thinking approach maximizes return on investment by avoiding complete system replacement as needs evolve.

Successful scalability planning involves standardizing on component systems that maintain compatibility across different sizes and applications. This strategy enables seamless integration of additional panels, lighting systems, or interactive elements without compromising existing display integrity. Companies benefit from reduced training requirements and simplified logistics when consistent systems are utilized across multiple events and locations.

Assembly and Installation Best Practices

Preparation and Tool Requirements

Professional installation of modular backdrops requires systematic preparation that includes component inventory verification, tool preparation, and workspace organization. Essential tools typically include hex keys, measuring devices, and level indicators to ensure accurate alignment and professional presentation quality. Preparation should also include reviewing venue-specific requirements such as floor protection, electrical access, and installation timeframes.

Successful installations benefit from predetermined assembly sequences that minimize handling and reduce setup time. Modular backdrops should be organized according to installation order, with frequently accessed components positioned for easy retrieval. This organizational approach reduces installation stress and ensures consistent results across different venues and setup teams.

Quality Control and Safety Considerations

Installation quality directly impacts both visual effectiveness and safety compliance, requiring systematic verification of connection integrity and structural stability. Each connection point should be inspected for proper engagement and secure attachment before proceeding to subsequent assembly steps. This methodical approach prevents installation errors that could compromise display stability or create safety hazards during event operations.

Safety protocols should address potential risks associated with tall displays, electrical integration, and public access considerations. Modular backdrops must comply with venue safety requirements and industry standards for temporary structures. Regular inspection of hardware components ensures continued reliability and identifies potential maintenance needs before they affect display performance or safety.

Graphic Design and Visual Integration

Design Principles for Modular Systems

Effective graphic design for modular backdrops must account for panel boundaries, connection points, and potential configuration variations. Design elements should maintain visual continuity across panel joints while incorporating flexibility for different layout arrangements. This requires careful planning of image placement, text positioning, and color transitions that remain effective regardless of specific configuration choices.

Typography and imagery must be scaled appropriately for viewing distances and lighting conditions typical in exhibition environments. Modular backdrops benefit from bold, high-contrast designs that maintain readability and visual impact across various viewing angles and distances. Design consistency across multiple panels creates professional presentations that reinforce brand identity and message clarity.

Production and Installation Considerations

Graphic production for modular backdrops requires specialized techniques that ensure color consistency and dimensional accuracy across multiple panels. Professional printing services should utilize color management systems and quality control processes that maintain visual uniformity throughout the entire display. Material selection must balance print quality with durability requirements and replacement cost considerations.

Installation of graphic elements should incorporate alignment references and attachment methods that ensure consistent presentation quality. Tension systems and mounting hardware must provide secure attachment while allowing for easy replacement or updating of graphic content. This flexibility enables regular message updates without requiring complete system replacement, maximizing long-term value and relevance.

Maintenance and Storage Solutions

Cleaning and Care Protocols

Maintaining professional appearance of modular backdrops requires systematic cleaning protocols that address both frame components and fabric elements. Aluminum frames benefit from regular cleaning with appropriate solutions that remove fingerprints, dust, and environmental contaminants without affecting surface treatments or finish quality. Hardware components should be inspected regularly for wear, corrosion, or damage that might affect functionality or safety.

Fabric care requirements vary depending on material specifications and printing technologies utilized. Most professional-grade display fabrics can be machine washed using gentle cycles and appropriate detergents, while others may require professional cleaning services. Proper care extends fabric life and maintains color vibrancy, ensuring consistent presentation quality throughout the service life of modular backdrops.

Storage and Transportation Strategies

Efficient storage solutions for modular backdrops must protect components from damage while maximizing space utilization and accessibility. Custom carrying cases or storage systems organize components logically and provide protection during transport and storage periods. Proper storage prevents component loss, reduces setup time, and maintains system integrity for reliable performance across multiple events.

Transportation planning should consider weight distribution, handling requirements, and vehicle space constraints. Modular backdrops offer significant advantages over traditional display systems by reducing shipping costs and simplifying logistics coordination. Compact storage capabilities enable cost-effective transportation to multiple venues while maintaining professional presentation standards that enhance brand image and marketing effectiveness.

Cost-Effectiveness and Return on Investment

Initial Investment Analysis

Evaluating the financial benefits of modular backdrops requires comprehensive analysis that considers initial purchase costs, ongoing maintenance expenses, and comparative alternatives such as custom-built displays or rental options. While quality modular backdrops may require higher initial investment compared to basic alternatives, the long-term value proposition becomes evident through reduced replacement costs, enhanced flexibility, and improved presentation quality.

Cost analysis should incorporate factors such as frequency of use, variety of venue requirements, and anticipated system lifespan. Modular backdrops typically demonstrate superior value for organizations participating in multiple events annually or requiring adaptable display solutions for diverse marketing applications. The ability to reconfigure existing components for different requirements eliminates redundant purchases and maximizes utilization of display investments.

Long-term Value and Scalability Benefits

The scalable nature of modular backdrops provides exceptional long-term value by accommodating changing business requirements and expanding marketing initiatives without complete system replacement. Organizations can start with basic configurations and add components as needs evolve, spreading investment costs over time while maintaining consistency in presentation quality and brand image.

Durability and reliability of quality modular backdrops contribute significantly to total cost of ownership by reducing replacement frequency and maintenance requirements. Professional-grade systems maintain appearance and functionality through hundreds of setup cycles, providing consistent return on investment while supporting professional brand representation across diverse marketing applications and venue requirements.

FAQ

What are the typical setup times for modular backdrops?

Setup times for modular backdrops vary depending on configuration complexity and team experience, but most standard configurations can be assembled by two people in 30-60 minutes. Simple straight-line displays may require only 15-20 minutes, while complex curved or multi-level configurations might take 90 minutes or more. Practice and familiarity with the specific system significantly reduce setup times.

Can modular backdrops be used outdoors?

Many modular backdrops can be used in outdoor environments with appropriate precautions and accessories. Wind resistance becomes a critical factor, requiring additional anchoring systems, ballast weights, or guy-wires for stability. UV-resistant fabrics and corrosion-resistant hardware are essential for extended outdoor exposure, and weather conditions should always be monitored for safety considerations.

How do I choose the right size modular backdrop system?

Selecting appropriate modular backdrops requires careful consideration of typical venue spaces, audience capacity, and presentation objectives. Start by measuring your most commonly used exhibition spaces and identifying minimum and maximum display requirements. Consider future expansion needs and choose systems that can scale from basic configurations to larger installations without component incompatibilities.

What maintenance is required for modular backdrops?

Regular maintenance for modular backdrops includes cleaning frame components after each use, inspecting connection hardware for wear or damage, and proper storage to prevent component loss or damage. Fabric elements should be cleaned according to manufacturer specifications, and replacement graphics should be ordered when image quality begins to deteriorate. Annual professional inspection ensures continued safety and performance standards.

EN

EN

FR

FR DE

DE PT

PT ES

ES AR

AR BG

BG HR

HR CS

CS DA

DA FI

FI NL

NL EL

EL IT

IT JA

JA KO

KO NO

NO PL

PL RO

RO RU

RU SV

SV CA

CA TL

TL IW

IW LV

LV LT

LT SR

SR SK

SK SL

SL ET

ET MT

MT TH

TH FA

FA AF

AF MS

MS SW

SW GA

GA KA

KA